FLEX APS is the manufacturing Planning and Scheduling software solution that supports all company planning processes from master planning to scheduling

Main features:

MASTER PLANNING

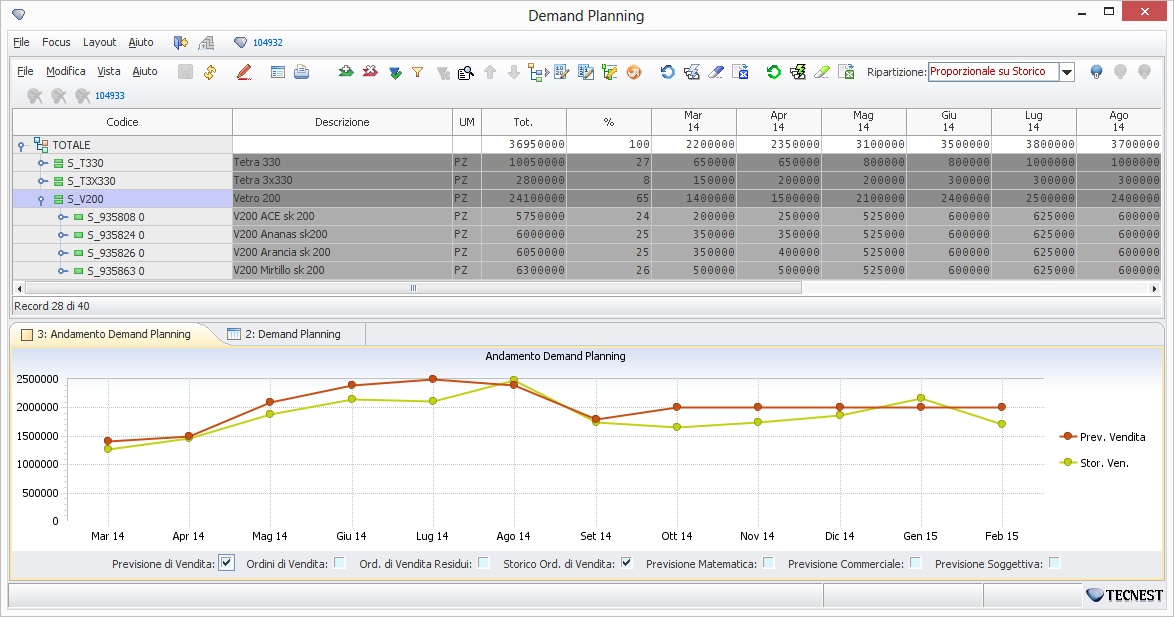

Demand Planning:

features for sales forecasting and demand planning. Sales forecasting calculation selecting the mathematical algorithm from a library, features for "backward" forecasting on past time intervals in order to make simulations and confrontation between the different algorithms, marketing intelligence features for manual correction on the plan and the creation of the final demand plan,reporting features.

Sales & Operations Planning (S&OP):

Marketing and Production plans are integrated in a single plan (Sales & Operations Plan) for production, inventory stocks and delays, by balancing demand and offer.

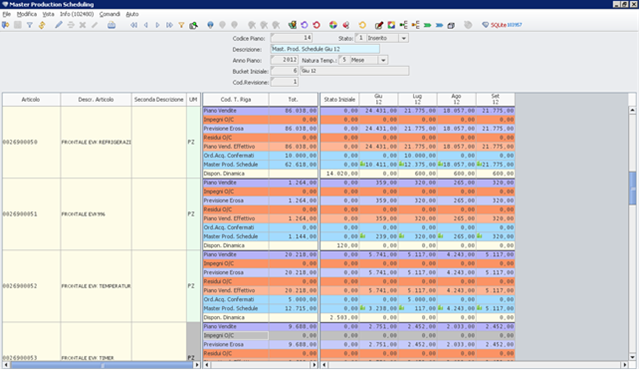

Master Production Schedule (MPS):

feature for demand management in terms of sales orders, sales forecast, internal orders, inventory reorder levels, which are the main components for the Master Production Schedule.

DETAILED PLANNING

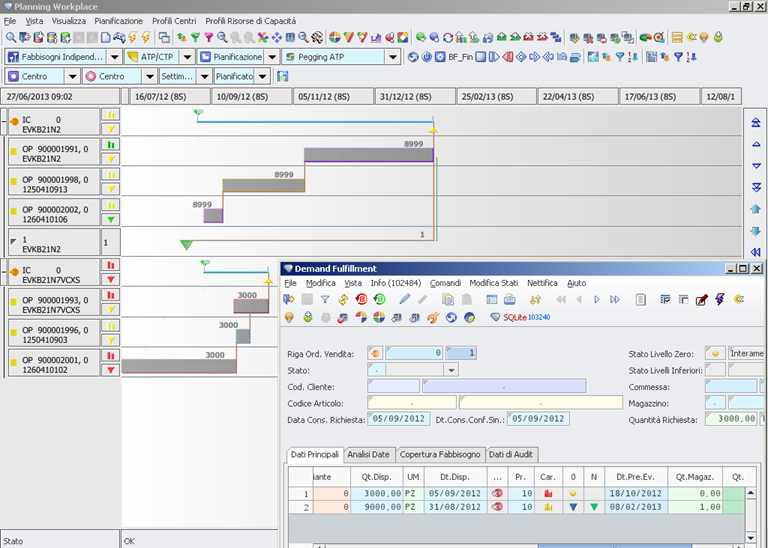

Demand Fulfillment:

it provides all business levels with the highest visibility on the process of fulfillment of market requests and demand: features to manage independent demand both in terms of order promising, giving customers a promised date, and in terms of sales orders' progress report.

Interactive ATP/CTP (Availabile/Capable To Promise) to check customer orders' feasibility:

it calculates customer orders dispatching dates according to the actual availability of end product, components and materials quantities and to production resources capability.

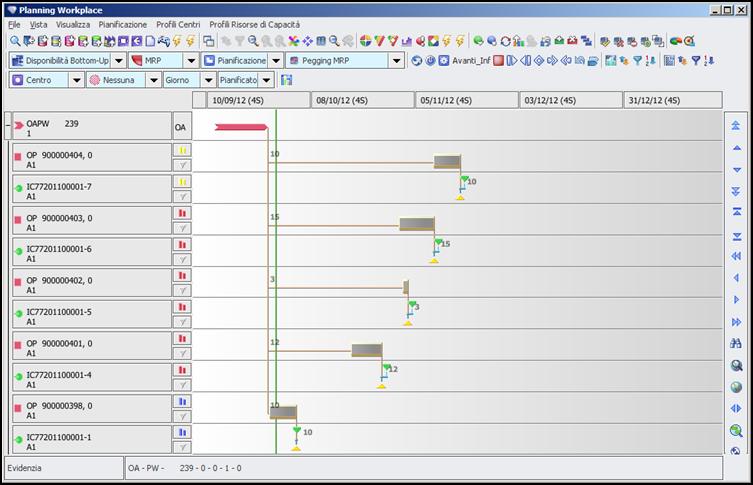

Fast-MRP, running in RAM, with interactive analysis of results (proposals and exceptions):

it integrates the output of the planning and scheduling process to complete the planning activity by checking if the requirements are fulfilled and, alternatively, by providing a proposal to fulfill the requirement with the missing material.

Interactive Graphic Full-pegging to track requirements-availabilities:

it compares, at all levels of the Bill of Materials, each requirements (in terms of sales forecast, customer orders, production commitment) with its availability (inventory stocks, production orders, outsourcing orders, purchase orders).

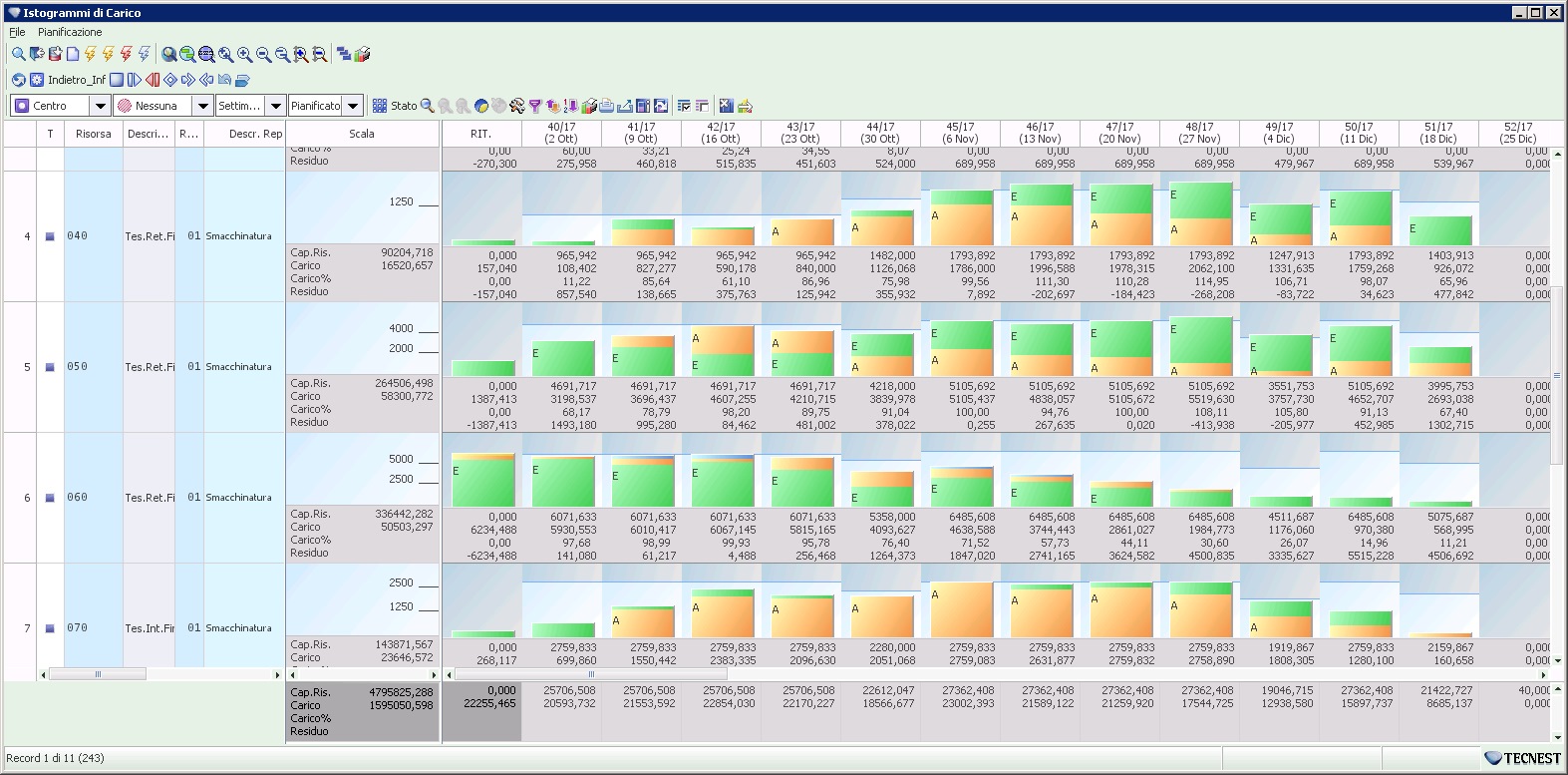

Finite and Infinite Resource Capacity Planning (CRP):

innovative approach to manufacturing resource capacity planning , both infinite and Finite, in accordance with backward, forward and mixed rules.

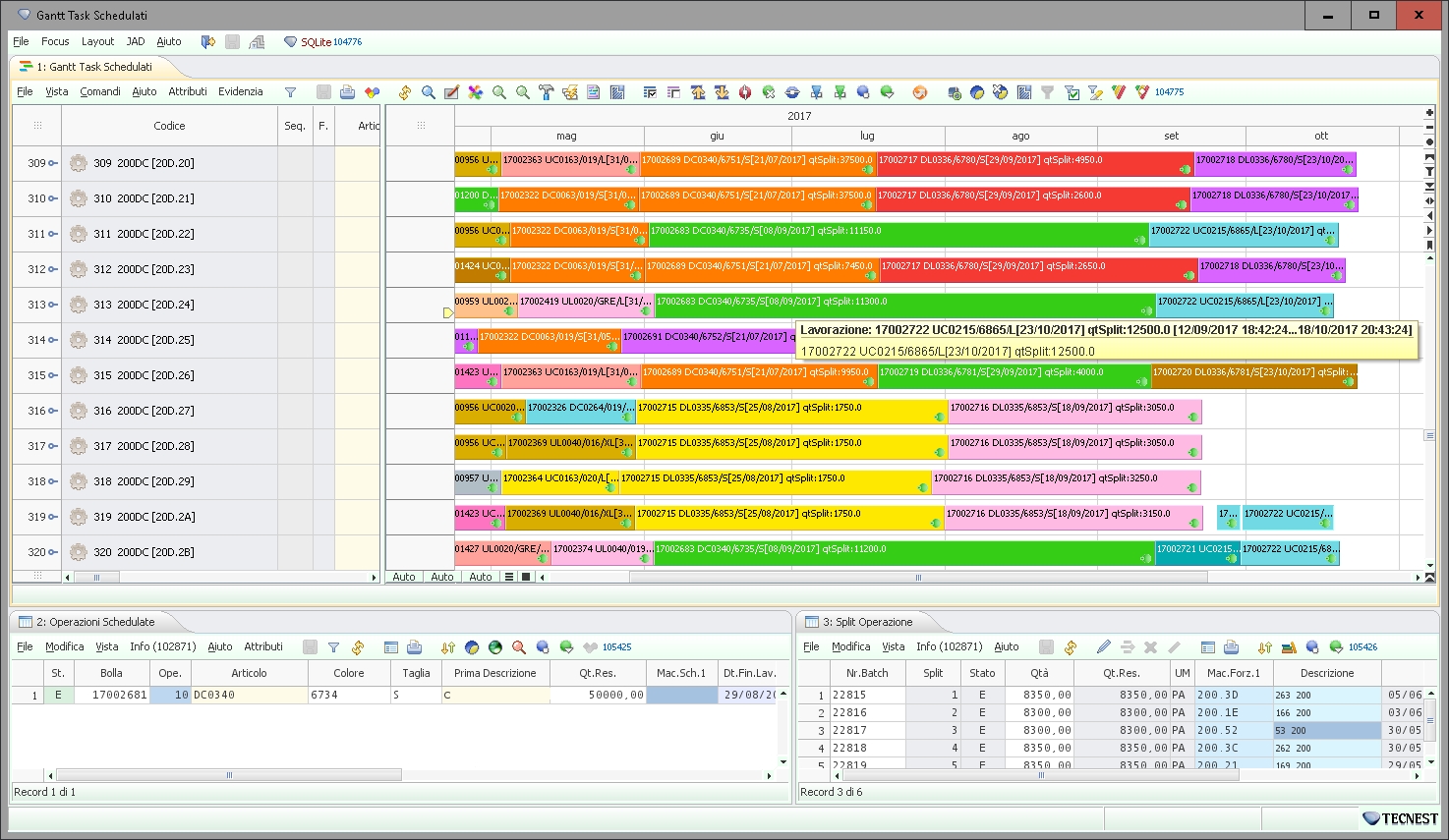

Finite Capacity Schedule of manufacturing resources (FCS):

it calculates the optimal sequence of work according to configurable objectives and to the model constraints (in terms of production capacity, technological issues, resources set-up, material availability).

Planning KPI with interactive simulation features:

performance analysis features to calculate specific Key Performance Indicators (KPIs) to evaluate the effectiveness of each production plan and choose the best one.