Coordinate and expedite the flow of work and materials within or between departments of an establishment according to production schedule. Duties include reviewing and distributing production, work, and shipment schedules; controlling machinery allocation and status; conferring with department supervisors to determine progress of work and completion dates; and compiling reports on progress of work, inventory levels, costs, and production problems.

His main tasks are:

-

defining productivity, quality, security standards and organize working activities

-

defining tools, machinery, plants and process plans check and monitoring

-

production planning

-

components and raw materials purchase management, inventory stocks, WIP and finished products

-

resources optimization

-

promoting WIP or finished products creation (Source: Isfol 2009)

Flex for Planning processes

In Production Planning & Scheduling processes, the role played by operational figures working on specific processes and activities is also very important. Among these main roles there are:

-

The Material Planner

-

The Process Manufacturing planner

-

The Production Planner

-

The Subcontracting orders Planner

Flex for Planning processes

Flex role-based features for Planning processes

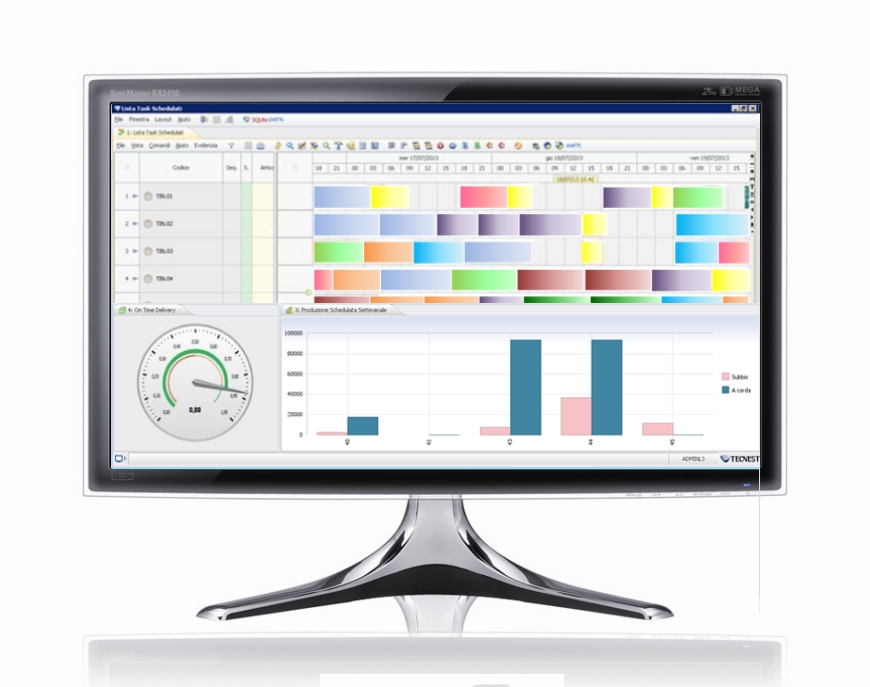

Thanks to role-based features, FLEX provides monitoring and analysis features for different business roles.

These features can be activated both on the system entry application, and on specific configurable dashboards, through multi-panel interfaces.

Each business role in a company has, therefore, a real-time access to features, information and KPIs, useful for his job.

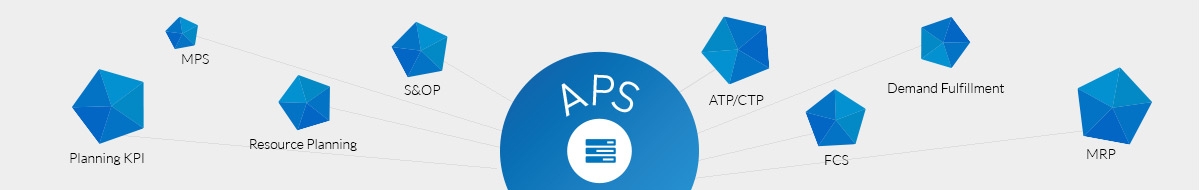

An example of the information and functionality available in the FLEX Advanced Planning & Scheduling area, are:

-

Service level trends and statistics in the last N months

-

Current Service Level indicator

-

Alert for overdue orders

-

Workcenters capacity trend in the last N weeks

-

Working outsourced hours and activities trends

-

WIP value in the last N weeks

-

Shipment delays trends

-

Missing material status by line

-

Confrontation of Scheduled orders vs Execution

-

ecc.

Advanced configuration tools: FOR YOU!

Thanks to the configuration features of Flex role-based features, the user does not only have to opportunity to choose the most appropriate business role among the ones available in the default configuration system, but can also configure and personalize his role and his dashboards on his own. By using the "FOR YOU" Advanced Application Tools, in fact, each user can independently manage and modify an existing configured role as well as build his own working panels, by selecting the features he needs from the User Application Panel.