- Company

-

Solutions

- Flex for Industry 4.0

- The Flex software suite

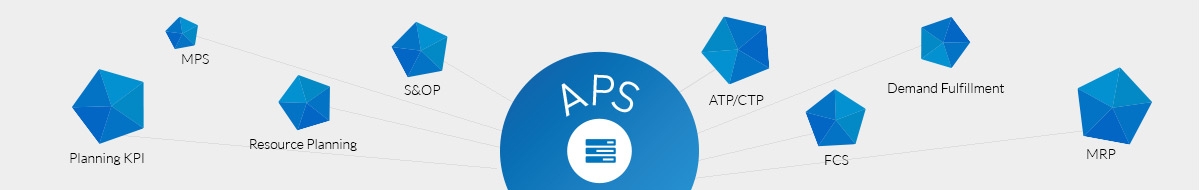

- Advanced Planning & Scheduling

- Manufacturing Execution System

- Total Quality Management

- Warehouse Management

- Total Productive Maintenance

- Operations Management

- Supply Chain Collaboration

- Product and Sales Configurator

- FLEX Advanced Dashboards

- FOR YOU Tools & Technology

- Culture

- References

- News

- Events

- Contacts

- Download Area